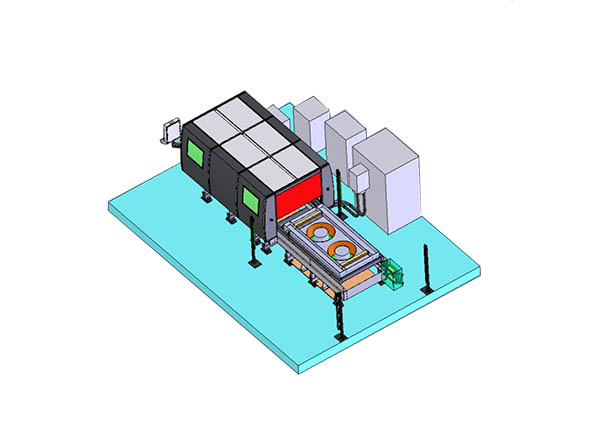

3D Metal Printing is an emerging technology with a presence in numerous industries including aerospace, defense, automotive, and manufacturing. Laser Photonics’s next-generation laser metal printing systems utilize the company’s proprietary technology to deliver incredible quality results at record-setting speeds. Each 3D Printer features a hermetic laser sintering chamber purged by high purity nitrogen, argon, and other process gases for an optimized sintering atmosphere.

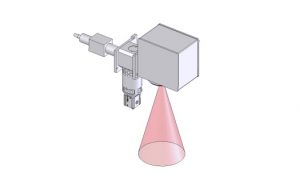

Built-in coaxial vision system – camera-based monitoring system for tool repair and inline fused materials quality verification.

Built-in coaxial vision system – camera-based monitoring system for tool repair and inline fused materials quality verification.

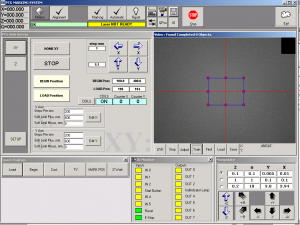

The two monitors show the GUI of the Laser 3D Printing Software and the Vision System Software.

Vision Server is an application which works with a video capture card to allow a user to create, or use, a training set from which the operator can search for a trained pattern.

All functions of Fonon Vision Server can be operated remotely either by command line or a graphical user interface. The Fonon Vision Server functions in conjunction with several “client” applications that allow third party software, such as Laser Photonics Fusion 3D, to remote control the Vision System.

All functions of Fonon Vision Server can be operated remotely either by command line or a graphical user interface. The Fonon Vision Server functions in conjunction with several “client” applications that allow third party software, such as Laser Photonics Fusion 3D, to remote control the Vision System.

Our Vision System implements pattern matching. This involves the training and locating of a known good pattern. Then finding X, Y, and Rotation angle offsets of similar patterns. X and Y can be assigned as any user defined units. This allows precision alignment of the laser pattern for selective 3D Laser Printing for the purpose of mold and tool repair. Vision system allows controlling porosity, allocating geometries, performing precision additive repair, detect and control build rate, conduct QC on the raw nano materials, inspect geometries, detect enclosures and particle coagulation, quality of powder deposition, and so on…

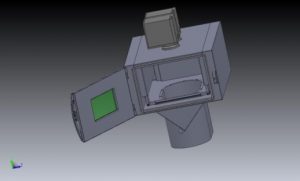

Our hermetic vacuum grade process chamber includes a laser rated protected viewing window to assist in nano powder re-deposition. The chamber includes 2 precision coated windows for viewing sintering laser beams, access powder collection containers, the powder feeding and receiving container as well as the powder delivery system.

Our hermetic vacuum grade process chamber includes a laser rated protected viewing window to assist in nano powder re-deposition. The chamber includes 2 precision coated windows for viewing sintering laser beams, access powder collection containers, the powder feeding and receiving container as well as the powder delivery system.

Our Vacuum grade process chamber reduces gas consumption, keeps feeding and receiving powder containers under a common atmospheric pressure build chamber in an inert gas atmosphere. This design concept reduces potential water vapor and gas below artificial valves including the dew point temperature. Finally, our build chambers are designed for single and dual head configurations.

In al mechanical systems Laser Photonics almost exclusively using the digital encoders as a part of company’s fully digital solution mechanical platform portfolio by providing highest dynamic performance with closed loop XYZ-stage precision, as well as comprehensive position feedback and process monitoring across the entire family of High and Low Power motion systems from Laser Photonics. This enables applications that require both high precision and high throughput, a property mix unachievable with conventional motion systems for beam-positioning or material positioning technologies.

Digital encoders are integrated into all of Laser Photonics Direct Drive motion systems; Fusion 3D Systems and Laser Comb dynamic focusing units. The use of closed loop digital positioning enhances precision without compromising dynamic performance or mechanical dimensions.

The Digitally controlled closed loop optical system exceeds the high dynamic performance of the industry proven galvo based solutions. It enables a laser traveling with a positioning resolution of 19-20 bits, exceptionally low noise value, best linearity and lowest drift. A comprehensive 20-bit communication is completed via LP’s family of high power systems featuring the industry’s first fully digital architecture. 3D Build pitch can be precisely adjusted for 3D layering applications and eliminates most of the unwanted effects leading to a geometry distortion.

Precision 3D applications require a small-spot-size laser beam to be precisely positioned within a large build area, LPC’s digital closed loop direct drive technology helps optimize build rate, precision, beam positioning speed, resolution and linearity, while substantially reducing drift effects.

The digital solution extensively enhances the range of diagnosis and communication capabilities between the 3D System and remote computer provides information on operating hours, serial number, manufacture information and essential operational data. Thus, defects can be quickly detected and eliminated.

To boost speed and/or positioning accuracy Laser Photonics can equip its digital servo firmware with multiple Control algorithms and parameter sets (tunings). Switching between different algorithms or sets (even during processing) allows Beam Positioning head dynamics to be reconfigured and thereby optimally adapted to particular task requirements.

Fusion 3D System Beam Positioning Heads allow real-time monitoring of all key operational states of the system, and equipped with coaxial vision system. As a result, the 3D Part build process can be simulated or monitored.

Each 3D System has external feeding and sealed recyclable powder containers with locks to allow their removal or connection while the process is running, keeping the entire process under inert atmosphere. One can replace the feed container without process interruption for adding NANO powder, or returning the overflow powder into the main system. Our simplified gravity based nano-powder dispense and recovery system not only reduces the size of our system on your production floor, but also eliminates closed-loop system, used by alternate suppliers, where inert gas is wasted as the transportation vehicle as well as unnecessary maintenance time cleaning the lines especially when changing metals for the next build cycle. The beauty of our simplified system materially reduces the introduction of moisture into the nano-powders and partial pressure in the build chamber that can lead to oxidation and other desirable elements during the build cycle.

Our 3D systems have incorporated years of laser system material processing and powder handling design experience, based on real life manufacturing industry requirements. From series production of implantable devices to complex lattice structures or detailed aerospace geometries, our 3D Printers are capable of fulfilling the requirements of a manufacturing system. With the extended Z-axis option it is possible to build parts up to a maximum height of 350 mm. All file and data preparation is done off-line in an office environment and while the system can be a tightly controlled manufacturing cell, the file preparation software also features useful process development tools for high level users.

3DF 3D Metal Printer

The 3DF–150 3D Metal Printer is designed to consistently meet the high demands of 3D printing in industrial and manufacturing applications

Applications:

- Fast-track prototype functional testing and market demonstration

- Manufacturing of highly complex geometries

- Manufacturing of customized or individually fitted parts

- Reduce weight applications

LaserComb 3D Metal Printer

LaserComb series of 3D metal printing system is designed for precision and rapid transition of metal printed parts from prototype to production based on a common family of geometric shapes and application-specific metal type.

LaserComb technology using one precision mechanical X-axis and one optical generating high resolution bit map image across the Y-axis, resulting in ability to use multi KW lasers to achieve high printing speed and consistent repeatability.

3DF-120D Dental 3D Printer

The 3DF-120D Dental 3D Printer is designed specifically for the dental industry to lower the price, and increase the performance of dental labs.

One of the most common applications of this system within dentistry is the quick production of custom-sized crowns, braces, implants, or surgical guides. Additive manufacturing allows a dentist himself to produce crowns very quickly following the scan of the patient’s teeth.

Desktop 3D Metal Printers

Each industry metal application requires different 3D metal printing system design procedures to achieve the desired specification and quality requirements even with similar horizontal cut dimensions.

Medical kneecap implant systems favor porosity for tissue integration with design structures to reduce weight while medical bone-healing devices favor optimum control of density to eliminate anomalies associated with stress related micro-fractures.

Custom 3D Metal Printers

Each industry metal application requires different 3D metal printing system design procedures to achieve the desired specification and quality requirements even with similar horizontal cut dimensions.

Medical kneecap implant systems favor porosity for tissue integration with design structures to reduce weight while medical bone-healing devices favor optimum control of density to eliminate anomalies associated with stress-related micro-fractures.