System Description:

The CleanTech™ Megacenter Laser Cleaning System is an Industrial-Grade Laser parts cleaning, rust removal and surface conditioning system with up to 36” x 36” of the working envelope. The CleanTech™ Megacenter operates as a standalone unit or can easily be integrated into a production line environment. The CleanTech™ Laser System is a 5 axis depainting, surface cleaning & conditioning system incorporating 3 mechanical XYZ axes coupled with 2 optical XY axes. It processes a wide range of materials with special attention to highly-reflective metals.

The CleanTech™ Megacenter is a Class I laser as designated by the CDRH and meets the full requirements for a stand-alone laser system as defined by 21 CFR 1040.10 under the Radiation Control for Health and Safety Act of 1968. As an added level of security, a redundantly switched safety interlock system helps prevent accidental exposure to excess laser radiation. Plus, the system is equipped with an electrical power manual reset, a key-locked laser power switch and a remote interlock connector.

There is an exhaust outlet for the Fume Extractor, powder coating for industrial durability which provides excellent protection for laser radiation according to CDRH requirements, and a Class IV operator-safe yellow transparent laser-rated acrylic viewing port for visualization of lasing processes and easier alignment. Finally, the system has audible and visible emission indicators with five-second emission delay settings.

| We Offer Our Customers… | |

|

|

- Eliminates Wet Chemical Cleaning Process

- Safe, Fast and Environmentally friendly

- Up to 42” x 42” Cleaning coverage for various flat and oversized parts

- Flexion Technology™ for Precise and Complete Laser Surface Cleaning

- Zero-Friction Direct Drive Motion System

- Full FDA requirements as a class 1 laser product

- Industrial-grade extruded frames with 19” rack mount design

- Exhaust outlet for Fume Extractor

- Fail-Safe Contact Lock front doors with Class 4 operator safe viewing port

- PC based controller, flat panel monitor, mouse and keyboard

- Operating Temp +18C to +25C: Relative Humidity (40-80%) non-condensing

- Designed for continuous performance under high-shock, vibration and dust conditions

- Easily reconfigured for direct installation into a production line environment

- Designed for maintenance-free Laser Surface Cleaning and Conditioning applications

- Standard wall plug operation with high electrical efficiency

- Low voltage power source (110/220 VAC) 8 amps

- High throughput with a palette loading/unloading table (Optional)

- 80 PSI Pneumatically Activated side sliding doors (Optional)

- Inert gas handling and selection system (up to 3 types of gas) for high quality surface conditioning and treatment.

- Red diode pointer for easy job setup

- 3D Dynamic Focusing System Upgrade Available

Follow the link to download pdf file with systems specifications:

- 2D Cleaning Head

- 3D Cleaning Head

- Depainting

- High Power Laser Surface Cleaning

- High Power Laser Surface Treatment

- Induced Surface Improvement

- Uniform Surface with low HAZ

- High Power Laser Paint Removal

- Subtractive Surface Treatment

- Surface Texturing

- Cosmetic Surface Conditioning (Replaces Bead Blasting)

- Tire Mold Cleaning

- Mold Cleaning

- Selective Paint Removal

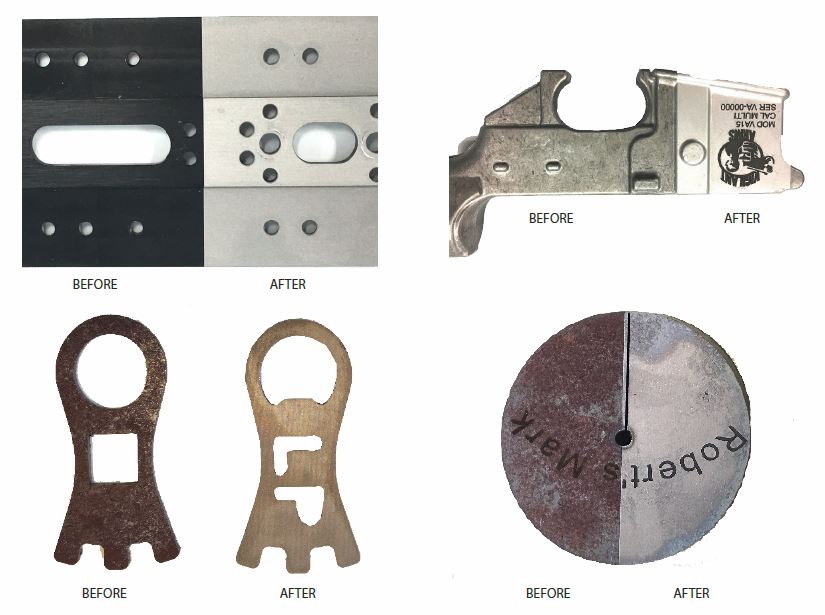

- Metal Parts Cleaning

- Anodizing Removal

- 3D Surface Cleaning and Conditioning

- Laser Cleaning

- “On-The-Fly” Laser Cleaning

- Laser Ablation (Anodized, Painted or Coated)

- Laser Paint Stripping and Removal

- Laser Rust and Corrosion Removal

- Laser Degreasing

More Information About the CleanTech Megacenter

See more on our Youtube Channel.