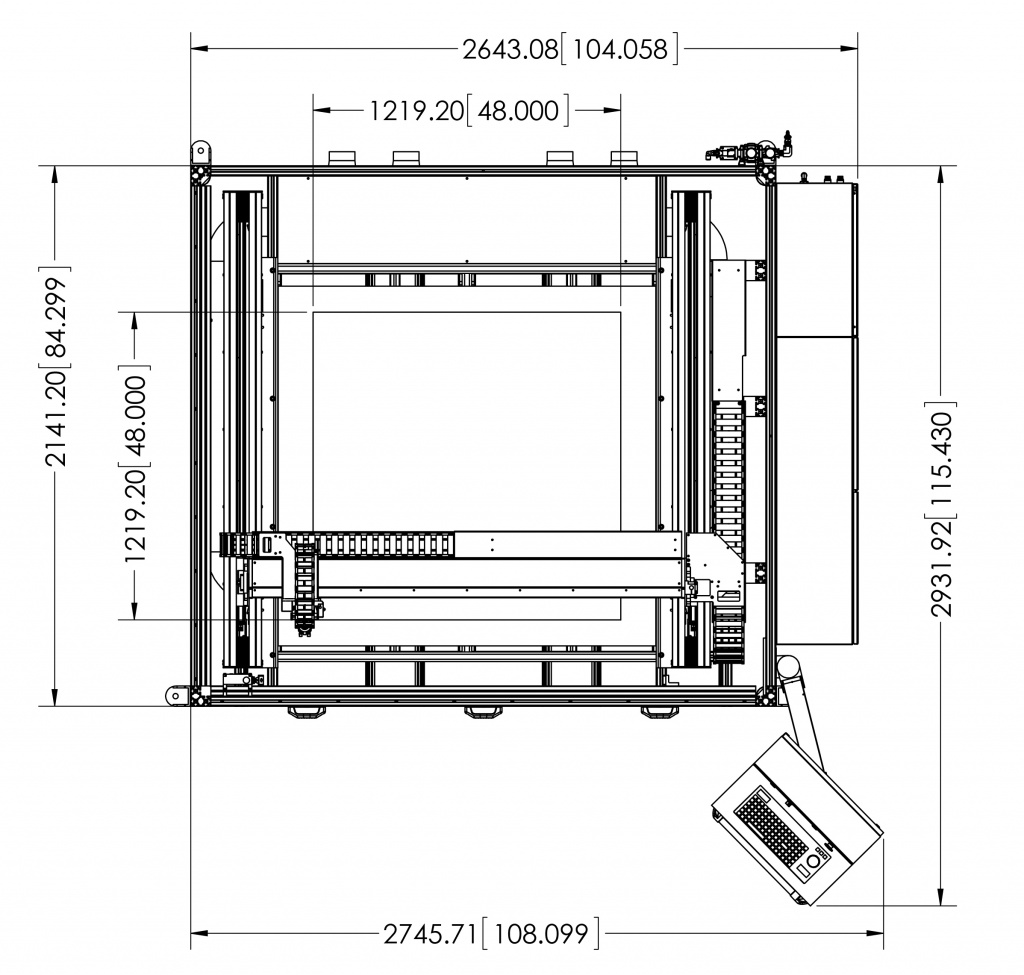

CNC Laser Cutting Machine

The SBM1200FL – is a flatbed multipurpose fiber laser cutting and engraving system built from state-of-the-art technology with customizable fiber laser power and a highly advanced direct drive motion and control platform with a high-pressure cutting head.

This system will achieve a level of quality and detail that is unprecedented in the industry for laser cutting and engraving. It can cut/engrave stainless steel, mild steel, copper, brass, aluminum, leather, nontransparent plastics, plaques, create stencils, and more. It has a replaceable nesting basket and can perform effective N2 or O2 gas-assisted cutting under pressures of up to 250 PSI. Ease of installation gives the system “plug-and-play” characteristics and a quick startup time.

The SBM1200FL will help quicken production time and lower manufacturing costs. This fiber laser reduces the cost of ownership, maintenance, and dramatically improves overall production quality. Given the operating cost savings, because of the high output laser power and low energy consumption, the SBM1200FL offers a two-year return on investment. The amount of detail preserved with the SBM1200FL is because of the direct-drive motor with software control. This software allows Laser Photonics to import ANY image into the software as a prepared solution for engraving/cutting.

- Direct drive structure means no belts, no rotary encoders, no gears, no wear, higher acceleration, higher cutting speed, and increased accuracy.

- Fiber laser is equipped with an optical isolator to stop reflections

- High-quality fiber laser power – up to 5000 Watts!

- 12″ clearance under the cutting head with 2″ of Z-travel.

- Purged gas: compressed air or Nitrogen (N2) protects the cutting head optics

- Sealed, high-quality linear bearings lubricated for life

- Software aligns the perpendicularity of the X and Y axes

- Standard programmable Z-axis: With 1.5’ (38 mm) stroke suitable for 3D machining.

- Replaceable 48″ x 48″ x 6″ nesting basket for different support surfaces: aluminum grating, honeycomb, and vacuum holding tables

- The latest generation of motion controllers integrate laser control functions, provide the fastest processing speeds, and optimize trajectory

- Maximum material size- 4′ x 4′ (1250 x 1250 mm)

- Material Thickness – See our Application Page

- Cutting Speed – Max. 1000mm/sec, 5000mm/s² acceleration

- Accuracy – +/- 0.020 mm

- High-pressure cutting nozzle with Oxygen (O2) or Nitrogen (N2) assisted gas for high-speed, clean cutting.

- System equipped with high-pressure oxygen laser cutting head for high-speed cutting of mild and stainless steel.

- The same system can also do marking and engraving on a variety of materials.

- Cutting highly reflective metals & materials

- High-speed sheet metal cutting

- Automotive frames cutting

- Coated & Plated Metals

- Anodized Aluminum

- Mild Steel

- Stainless Steel

- Anodized Aluminum

- Aluminum

- Copper

- Non Clear Plastics

- Different Alloys

- Coated And Plated Metals

- Thick Coating Removal

- Deep Engraving

- Stencils & Masks

- Vector And Bit Map

- Leather

- Dieboards

- Shipbuilding

- Signmaking

- Control Panels

- Plaques & Awards

- Fiber Optic Beam Delivery System

- Access From The Front And Back

- Simple Operation Panel

- Auto Focus Cutting Head

- Replaceable Nesting Basket

- Native G-Code Cnc Programming

- Standard Cnc Control

- 4’ X 4’ Standard Cutting Table Size

- With Optional 4’ Extension Table Extends Cutting Area To 4’ X 8’.

- 1000 Watt Fiber Laser

- Available Custom Systems With Up To 50,000 Watt Fiber Laser

- Software Controlled X Y Orthogonality

- High Pressure Gas Assist N2, Argon Or O2 Gas-Assisted

- Cutting Under Pressures Of Up To 250 Psi.

- Class 1 And Class 4 Laser Safety Enclosures

- Processes Most Commonly Used Materials For 1064 Nm Laser Wavelength.

- Highest Cutting Quality Available From 1.06 Mkm Lasers

- Latest Generation Ytterbium Fiber Laser With Up To 5.000 Watt Cw

- Fastest Cutting Speed On The Market For Comparable Systems

- No Optical System Alignment, No Laser Service Necessary

- Low Power Consumption, No Need For High Power Outlet

- Software Alignment On Orthogonality

- No Laser Service Knowledge Required From The Operator

- No Alignment After Optics Replacement

- No Beam Delivery System Maintenance

- Lowest Operating Cost Among All Laser Types

- No Replacement Parts On Laser Necessary

- Save Valuable Work And Floor Space, The Unit Has A Small Footprint, Is Ethernet

- Ready And Plug- &-Play Capable.

- Ease Of Installation Allows For Quick Start-Up

- Fully Software Controlled Mechanical Geometry Alignment Eliminating Special

- Requirements For Installation

- No Re-Education Required For Experienced Cnc Operators

Visit Our Youtube Channel.