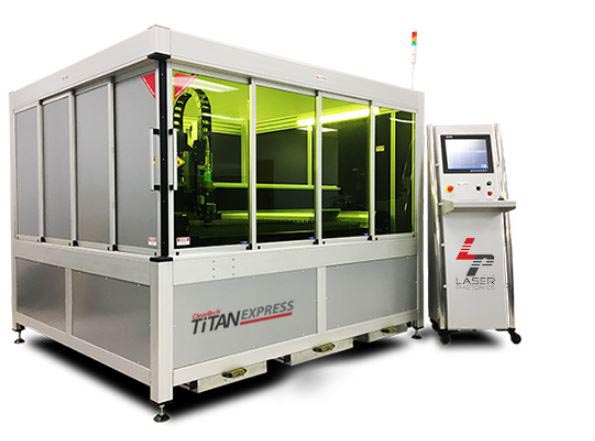

CNC Laser Cutting Machine

The Titan Express laser cutting machine by Laser Photonics provides agility, responsiveness, and speed unseen in a unit of this size and price. The Titan Express combines cutting edge motion engineering, CNC control, and the latest fiber laser cutting technology into one unit that is unique to the laser industry. Titan Express is equipped with a high-power, energy-efficient fiber laser, and an advanced direct drive motion-controlled platform – making it the best machine for cutting highly reflective materials (including stainless steel, aluminum, brass, and copper).

The Titan Express has the fastest cutting speed on the market. This system features reduced energy consumption and 1/3 of the operating costs over other laser machines. The Titan Express’ fully software-controlled geometry alignment eliminates the need for special installation requirements. The Titan Express requires no optical system alignment, laser service, or laser replacement parts making this system virtually maintenance-free.

| Titan Express Benefits | |

|

|

- Sheet Metal Cutting

- Precision parts fabrication

- Highly reflective metals Cutting (brass, copper, aluminum)

- Coated & Plated Metals Cutting

- Titanium Cutting

- Size (ft.): 4 x 4 [1.2m x 1.2m]

- High pressure gas assist N2 Ar or O2 gas-assisted cutting under pressures of up to 250 psi

- Easy Loading & Unloading of Materials

- Oversized Class 1 Laser Viewing Windows with LED Lights

- Water chiller

- Software controlled X-Y orthogonality

- Control terminal with touch screen monitor

- Diode pointer for visual alignment

Advanced laser technology benefits

The Titan Express Fiber Laser Cutting Machine is built upon the latest innovations in fiber laser technology with the following benefits:

Lowest Cost of Operation

The Titan Express consumes less than 5% of the power required by a CO2 laser system with the same output wattage.

Placement Accuracy

The Titan Express’ laser provides the highest possible accuracy and repeatability, resulting in the smallest possible penetration point and the finest edge control.

Modular

Users can increase their laser cutting power of 1kW,1.5kW, or 2kW.

Upgradeable in the Field

No need to remove the system from the production line.

Adaptive thin-to-thick beam shaping

The Laser Photonics laser auto focuses while in operation, adapting its focal point dynamically to account for changes in the thickness of the material being processed.

Cleanest Cut in the Industry

The beam produced is highly precise and slim, lower than 0.1 mm. This eliminates the discoloration on either side of the cut caused by conventional laser cutting methods; delivering the lowest Heat Affected Zone (HAZ) available. This is ideal for all highly-reflective metals 1” thick or less.

CleanCut technology eliminates burns around corner areas caused by the laser during cutting. This provides a perfect cut and the highest quality edges possible, and is particularly effective on highly-reflective materials including aluminum, copper, bronze and steel.

Simple Beam Delivery—The Titan Express uses fiber optic beam delivery, a state-of-the-art technology ensuring the most consistent beam path.

Conventional laser cutting methods are complicated, using articulated arms and CNC beam length compensation and requiring constant aligning of the optics. This results in different cutting qualities in different areas of the work table. Laser Photonics’ fiber optic beam delivery contains no moving parts in the beam path, guaranteeing consistent cutting conditions over the entire work area.

TurboPiercing technology—a standard on all Titan Series systems, TurboPiercing guarantees the fastest and most consistent piercing speeds available. Unlike conventional methods, TurboPiercing technology creates an accurate hole, avoiding unnecessary craters in the material.

Plasma Shield technology—When transitioning from straight line cuts to corner cuts, Plasma Shield technology precisely restricts plasma generation.

Conventional CO2 lasers cut a deformed edge while maneuvering corners, resulting in an inferior cut quality and minimizing production acceptance. Laser Photonics’ Plasma Shield technology tightly regulates acceleration speed, controlling plasma generation while maintaining superior quality and production throughput.

See More Financing Options.

More Information About Laser Cutting.