Laser Photonics offers a wide array of ready-made aerospace solutions, from direct parts marking, UID and deep engraving to our newest CleanTech laser cleaning systems. The Aerospace industry represents the nation’s leading manufacturers and suppliers of civil and military components, equipment, services, and information technology. As companies in the industry look to integrate new state-of-the-art laser solutions into their current processes, Laser Photonics stands ready to support them with the best laser-blasting and surface conditioning systems on the market today. On top of corrosion and coating removal, this cutting-edge laser blasting technology can be utilized by professionals in the aerospace industry to clean aerospace fixtures, perform selective paint removal on rivets, and more. Laser Photonics laser cleaning systems provide the most cost-effective, time-efficient, environmentally friendly, and safe industrial cleaning method.

The importance of direct parts marking, UID and deep engraving during the manufacturing process continues to increase globally. This increase in importance is due to how these practices streamline traceability, production flow control, inventory control and renewal, service marks, product quality validation, long-term product liability and reliability. These occurrences have resulted in the United States government and the Department of Homeland Security approving a variety of programs which has resulted in lasers becoming an essential part of the present and future of direct parts marking, UID (Unique Identifier), and deep engraving. In the private sector, a variety of government contractors have already elected to utilize laser technology to comply with strict government regulations.

Laser Photonics’ cutting-edge laser blasting technology was developed to match and exceed strict industry standards. The quality of our products surpassed industry needs and was transferred to numerous markets and industries for the benefit of our existing and future customers.

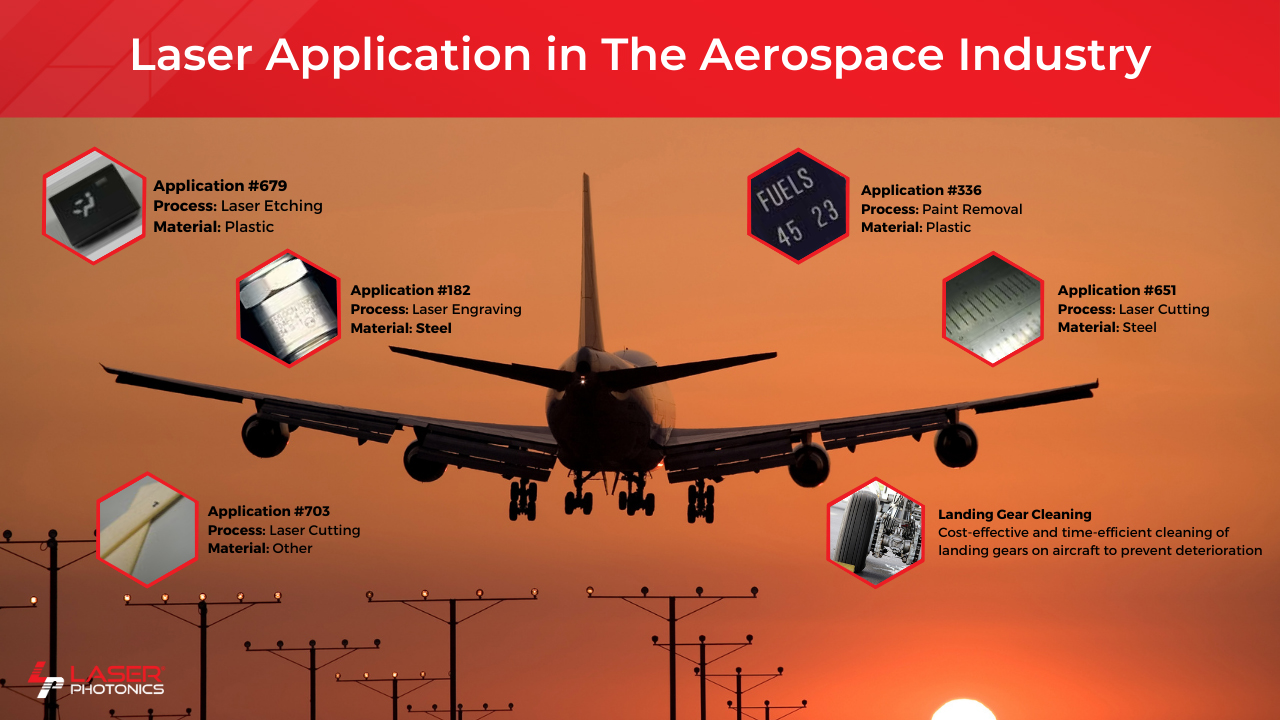

Aerospace Application Examples

Our technology provides efficient, maintenance-free, non-destructive and non-dimension-changing solutions for the following applications:

- Permanent marking on jet engines parts, igniters, spark plugs, turbines, and tools

- Surface Profiling, surface conditioning, and cleaning of jet engine parts

- Service and identification marks

- Foldable solar panels and glass components

Application #651

Process: Laser Cutting

Material: Steel

Application #182

Process: Laser Engraving

Material: Steel

Application #336

Process: Paint Removal

Material: Plastic

Application #505

Process: Laser Engraving

Material: Aluminum

Application #679

Process: Laser Etching

Material: Plastic

Application #703

Process: Laser Cutting

Material: Other