Does laser battery cleaning improve performance?

The Infrastructure Investment and Jobs Act sets aside $6 billion for grant awards to expand U.S.-based battery R&D. See Our Lasers in Action! Batteries With Applied Laser Cleaning Up to* 0 % Increased Electrode Capacity 0 % Increased Lifespan Laser Cleaning Application for Batteries Lithium batteries are made up of ...

Read More

Read More

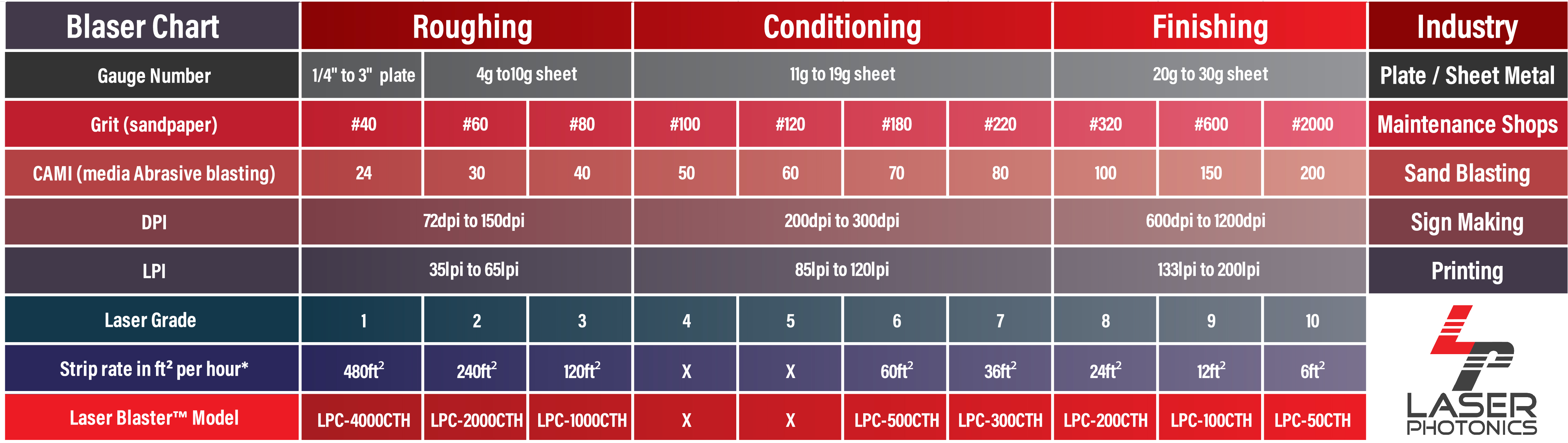

An Industry First: Laser Photonics Develops Laser Characteristics Standards

Laser Photonics (LP) has developed a laser characteristics matching system that sets standards for measuring the performance of industrial laser materials processing equipment. This industry first is designed to take the mystery out of choosing the right laser to achieve desired results in industrial materials processing. By Mark Kouri Sandpaper ...

Read More

Read More

How would you remove powder coating?

Powder coating is made to last. So what if we want to remove it? Photo by Teddy Österblom on Unsplash CleanTech™ 50CTH, 100CTH, and 200CTH strip powder coating from steel plat in real time We like powder coating. These protective finishes don’t just look deep and rich; they are, flexible, ...

Read More

Read More

How to Choose the Right Laser Blaster for You

Almost every laser manufacturer in the market categorizes their laser systems by their power. Whether a laser is powered by 50 watts or 4 kilowatts, its power consumption by wattage is not the best indicator of the materials processing results it achieves. If that was the case, then there would ...

Read More

Read More

New Portable Handheld Laser Marking Machine Announced

Laser Photonics announces the newest model of the Handheld MarkStarPro. Smaller and lightweight design with all cables enclosed plus the versatility, high performance, and rugged portability of our Handheld Series. The MarkStarPro is designed for a wide range of engraving and marking applications in the field or around the shop. The MarkStar can mark on many materials, sizes, and locations ...

Read More

Read More

Lasers in Automotive Industry : Application Newsletter

Application Newsletter: Lasers in Automotive Industry Using Laser Cutting in the Auto Industry - an Applications Newsletter Laser use in automotive manufacturing dates back to Ford Motor Co in the mid 70’s. Lasers were used initially for under body welding for an assembly line. Today, lasers are used in nearly ...

Read More

Read More

Hitting The Mark For Heavy Equipment Etching and Marking

Do you have heavy equipment or assets in the field that need to be marked? Are parts too big for regular marking machines? Don't bring them in to be marked, take the MarkStarPro to them! It's the rugged and remote laser marking solution you need. The MarkStarPro is a portable-hand-held 3D ...

Read More

Read More

Laser Marking Systems for Ballistics Identification Applications

Controversial microstamping identification requirements now achievable via advanced laser marking and engraving systems LAKE MARY, FL, April 3, 2016 – Laser Photonics today announced application-specific advancements in the controversial area of microstamping, a method of tracing bullet casings and cartridges back to the weapons from which they were fired. The ...

Read More

Read More

Laser Marking Systems for Circumferential Marking Applications

Latest System is Economical & Efficient Compared to Dot Peen or Inkjet Marking Orlando, FL, March 21, 2016 – Laser Photonics announced an update to the LaserTower Professional CM Series, a line of direct parts marking system with advanced programming capabilities and an integrated rotary axis, providing the ability to ...

Read More

Read More