Latest News from Laser Photonics

Product Updates

Press Releases

Application Updates

Technology Updates

Media Mentions

Q4 2023 – Q1 2024:

Past mentions:

– Click on image to read or download –

Online articles:

Laser Photonics Corporation (NASDAQ: LASE) Provides Strategic And Operational Update – A Look Into What This Means For Shareholders

December 21, 2023

Why Partners Like NASA Trust Laser Photonics With Their Laser Cleaning Needs

December 14, 2023

Even As The Industrial Cleaning Industry Shifts From Abrasive To Laser, There Are Risks Involved – Laser Photonics Places Safety First

March 20, 2023

How Laser Photonics Corp (NASDAQ: LASE) is Using Advanced Technology to Revolutionize the Abrasive Cleaning Market

February 12, 2023

3 Laser Stocks Beating the Dow Jones in Q1 2023

February 5, 2023

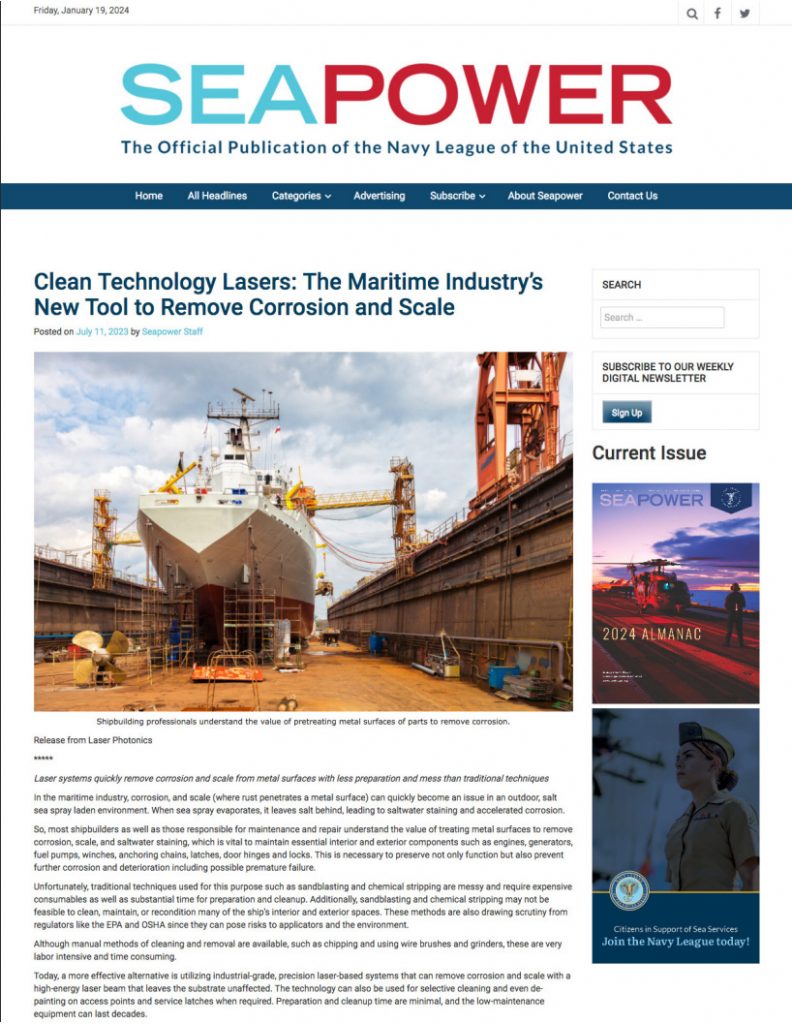

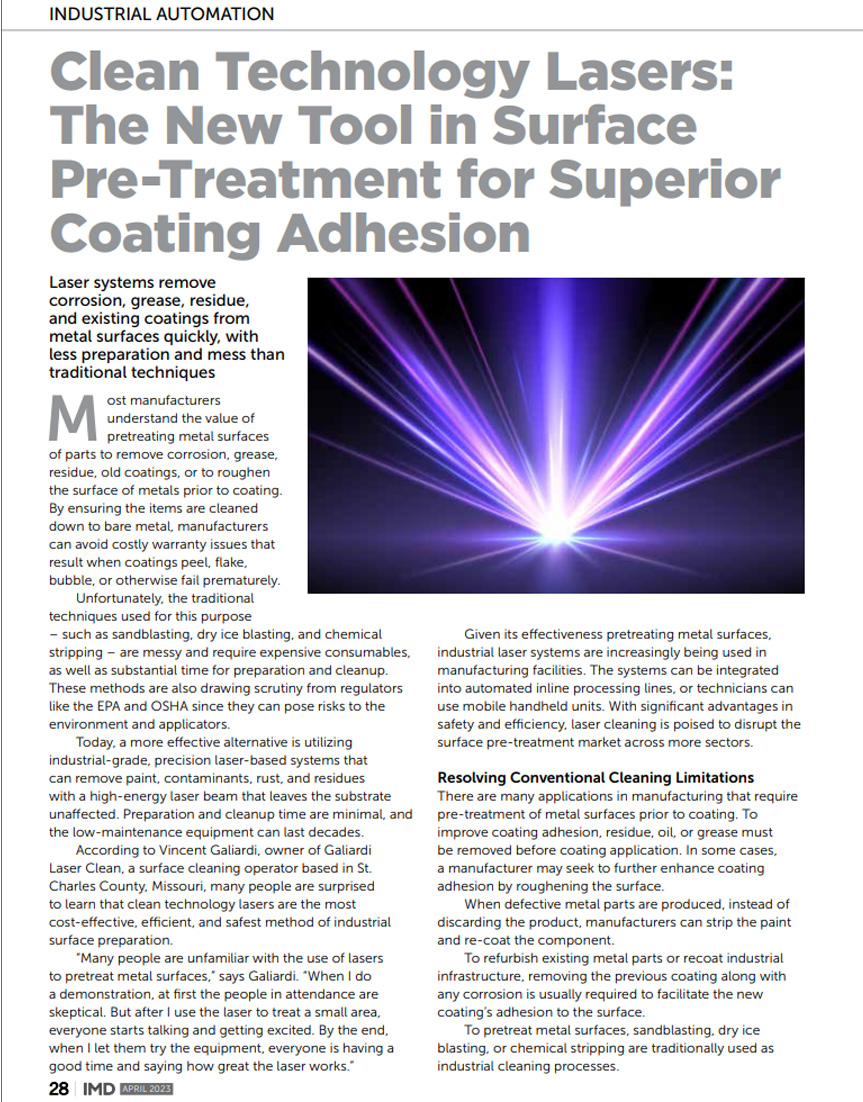

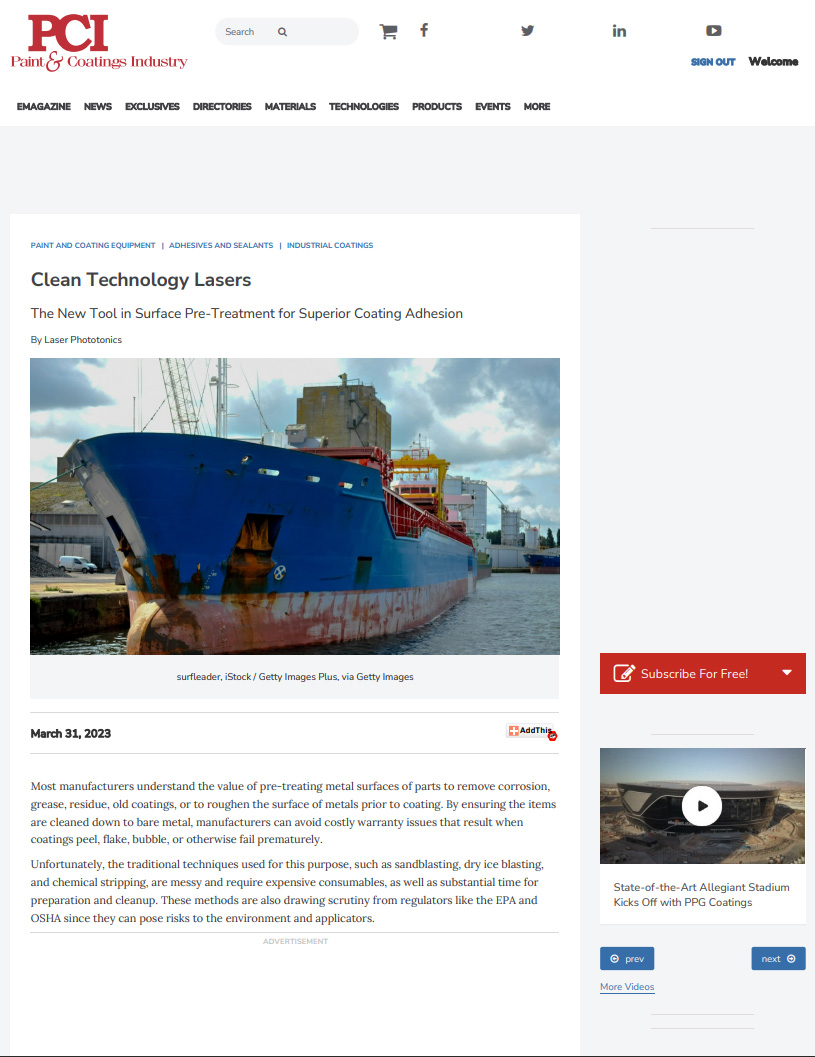

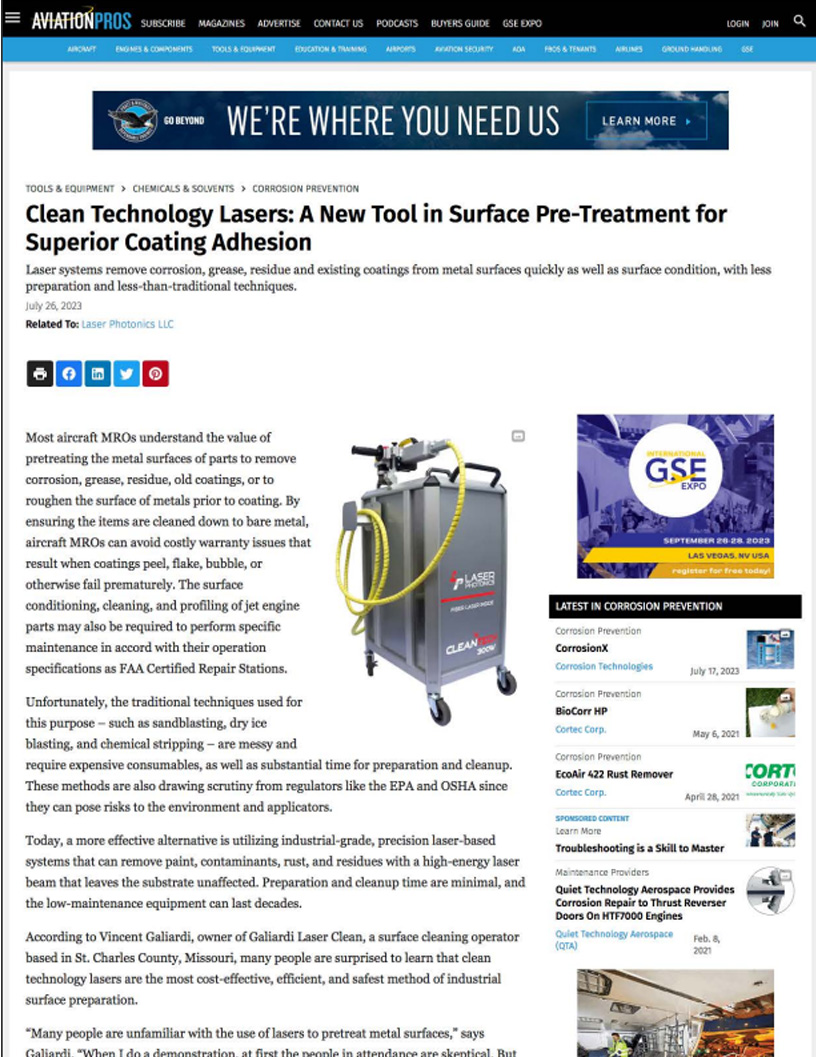

Clean Technology Lasers: The New Tool in Surface Pre-Treatment for Superior Coating Adhesion

February 2, 2023

Laser Photonics Addresses Stock Performance Since IPO

October 10, 2022

Laser Photonics Highlights Key Investment Points for New Investors

October 6, 2022

Laser Photonics Announces Appointment of Timothy Schick, CFA, as Chief Financial Officer

October 5, 2022

Laser Photonics Announces Closing of Initial Public Offering on Nasdaq

October 4, 2022

With A Small Float, 133% Upside, Fortune 1000 Clients, and Game-Changing Tech, LASE May Be One of the Biggest Rebounds Today as the Markets Setup for an Epic Rebound!

October 3, 2022

The Top 5 Laser Stocks with a Potential $723.9 Million Opportunity

September 30, 2022

Laser Photonics Announces Pricing of Initial Public Offering

September 29th, 2022

Laser Photonics Launches CleanTech(TM) 3000-CTH Laser Cleaning

May 9, 2022

Laser Photonics Announces Annual Report Filing to SEC

April 19, 2022

Laser Photonics CleanTech(TM) Line Expanding – Coming Soon!

April 12, 2022

Laser Photonics Corp Files Quarter Three Findings

November 16, 2021